Global Network

Servier offers you the flexibility of 16 state-of-the-art manufacturing sites worldwide.

Warsaw, Poland

Manufacturing activities were established in Warsaw 27 years ago. In that time, we have focused on providing high quality pharmaceutical products to patients in Poland and beyond.

Servier has recently invested in the facilities in Warsaw to maintain the highest standards of manufacturing operations. Our highly experienced team offers our clients comprehensive contract development and manufacturing services from process scale-up and analytical services to commercial manufacturing.

Products & Services

Warsaw Guided Tour

Continuous quality improvements are applied to our equipment, organization and processes that have resulted in shorter lead times and lower production costs. We are inspected by global regulatory agencies and have a proven track record of success in regulatory inspections.We apply our high standards across all aspects of our development and manufacturing processes.

Our clients benefit from customized service and support for each stage of the project. We have the manufacturing capacity for your project and a dedicated team to help you.

Key Capabilities

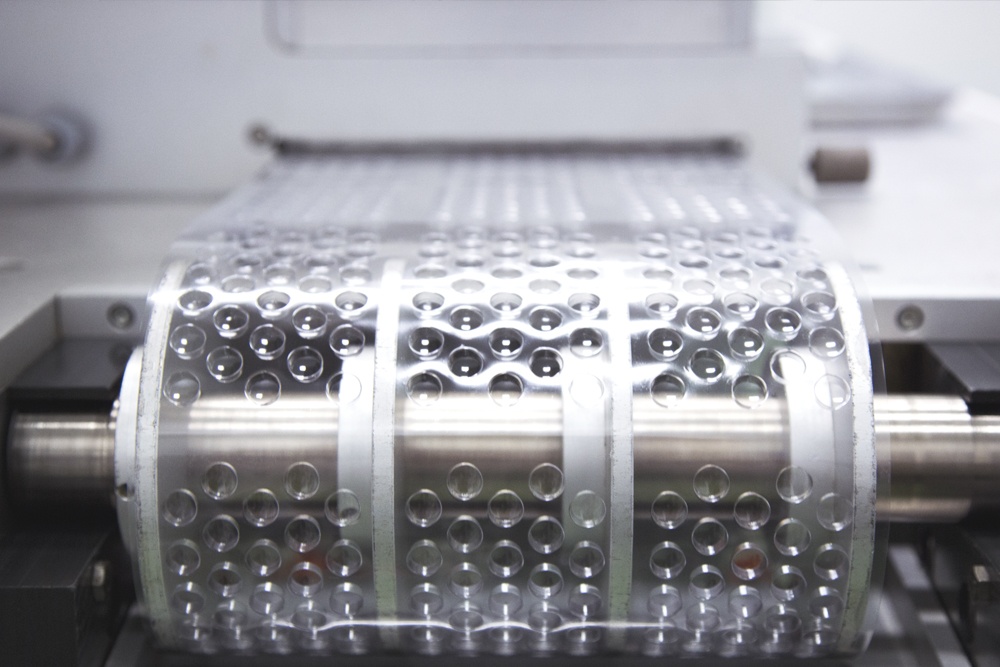

- Oral solid dose forms manufacturing

- (granulation, tableting and film-coating, encapsulation)

- Technology transfer, process validation, process optimization

- Packaging of tablets and capsules in blisters, PP and HDPE containers

- Serialization, aggregation technology and tamper-evident solutions

- Scale-up manufacturing

- Distribution into 21 countries

Analytical Capabilities

- Comparative dissolution profiles

- Stability studies:

- ICH (25°C/60%RH, 30°C/65%RH, 30°C/75%RH, 40°C/75%RH)

- On-going stability studies

- Products in bulk

- Products packed in blisters, bottles

- Stability in-use

- Inter-Lab comparative trials

- Transport validation

- Registration services enabling CMC submission

- Physico-chemical and microbiological analysis:

- Chemical control of excipients, semi-finished products and finished products

- Analytical methods transfer

- Microbiological control of materials, semi-finished products and products

- Validation of microbiological methods

- Packaging materials analysis

Key Equipment

- Wet granulation (High-shear Bohle) 300L

- Wet granulation (High-shear Glatt) 150L

- Fluid bed drying (Glatt) 300L

- Fluid bed drying (Glatt) 150L

- Dry mixing (Direct compression) 30L – 800L

- Oscillating and rotating sieve mill

- Tableting machines (Fette-Courtoy) single output

- Capsuling machine GKF2600

- Spray coating (Glatt) 170L – 190L

- Spray and sugar coating (GS) 150L

Facilities Capabilities

Download